Plastics are used in almost every places in our daily life and production. Among them, some are high grade material. Thus the price is higher. While some are general ones with low price. Thus some supplier may use cheap material for some products in which should use high grade material. Thus they can save much of cost. But this will cause hose fail and reduce its service life.

Then how to distinguish the materials to avoid such problem? Here with you 4 methods to do that.

Density method

Examine the density of each of them. Use liquid as the medium and test if they float on the surface or sink down. Then you can roughly know the types of plastic hoses, such as a piece of plastic pipe placed in water, floating on the water surface can It is concluded that the raw material is not PVC (due to the density of PVC>1).

Combustion method

mainly examine the color of the flame and the smell and smoke emitted during combustion. Generally speaking, the burning flame of polyolefin raw materials is mostly black or light blue, with a mild and light smell and white smoke, and most of them have Benzene or chlorine raw materials are prone to black smoke and strong smell after burning. In addition, such as PE and PP have drip ignition. While PVC, etc. have no drip ignition, but have self-extinguishing.

Optical method

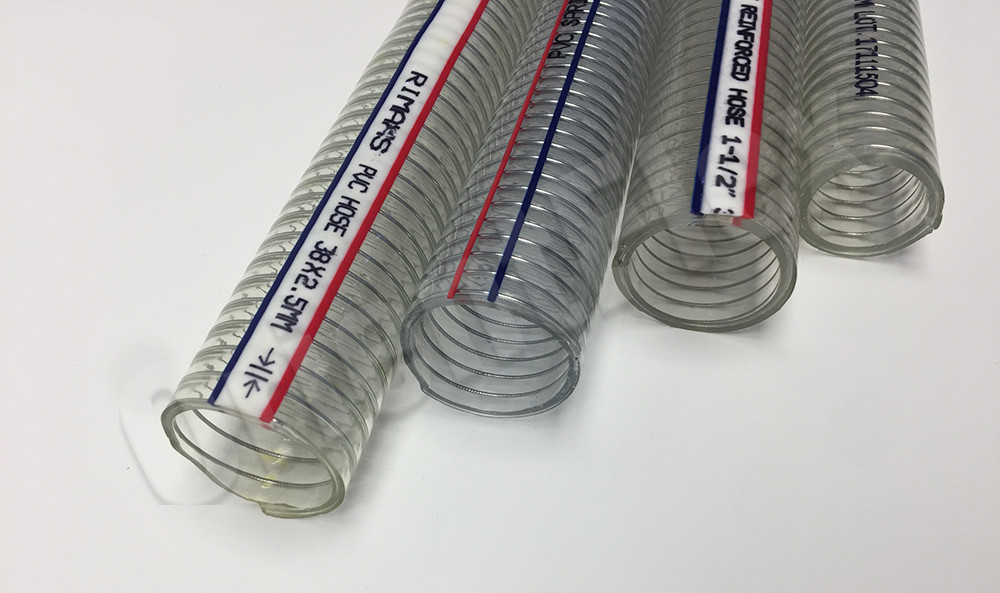

It mainly examines the clear of raw materials. Commonly used clear raw materials are: PS, PC, PMMA, AS; translucent raw materials are: PE, PP, soft PVC, clear ABS, etc. The other materials were essentially opaque.

Color method

Generally speaking, if the raw material without additives contains double bonds, the color will be slightly yellow, such as ABS. The polymer still contains double bonds. Therefore it will appear slightly yellow.

Most of the other identification methods will rely on various instruments, such as nuclear magnetic resonance, thermal scanning, thermal analysis and so on.